玻璃涂布機設備解析:技術分類洞察

時間:2025-06-09 來源:http://www.szmdk.com/ 發布人:昌盛機械

玻璃涂布機作為特種加工設備,在建筑節能、光伏新能源、顯示面板等領域發揮關鍵作用。其技術演進不僅體現在涂布精度提升,更在于對復雜工藝需求的深度適配。本文從設備分類、技術特性、應用場景三個維度,解析玻璃涂布機的技術體系與發展趨勢。

As a special processing equipment, glass coating machines play a key role in building energy conservation, photovoltaic new energy, display panels and other fields. Its technological evolution is not only reflected in the improvement of coating accuracy, but also in the deep adaptation to complex process requirements. This article analyzes the technical system and development trend of glass coating machines from three dimensions: equipment classification, technical characteristics, and application scenarios.

一、設備分類與技術路線

1、 Equipment classification and technical roadmap

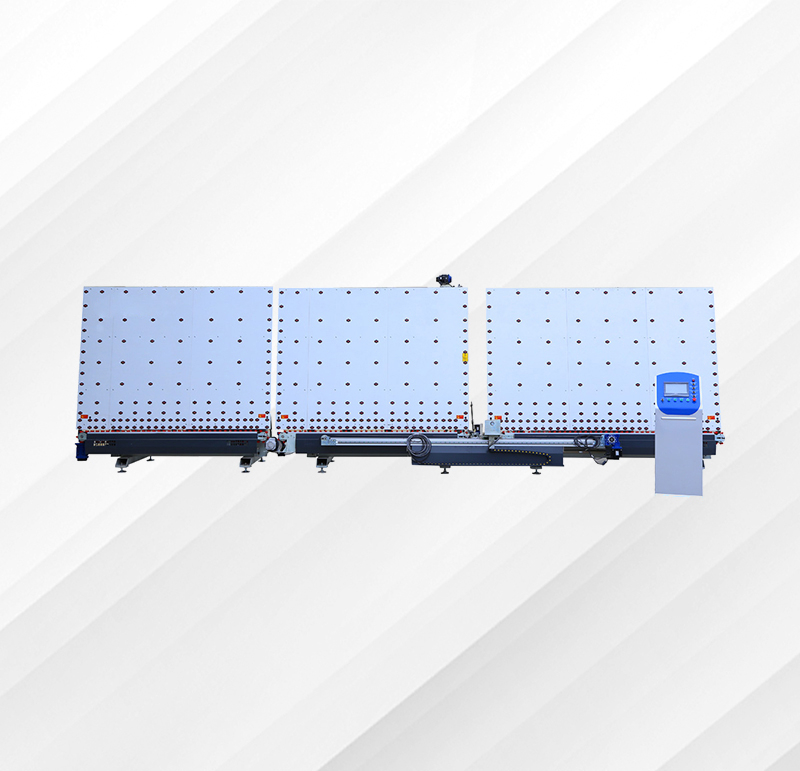

狹縫式涂布機

Slit type coating machine

該設備通過精密加工的模頭形成均勻液膜,涂布厚度可控制在微米級。某研究機構的數據顯示,采用變隙式模頭設計后,涂布厚度均勻性CV值可降至0.8%以下。其核心優勢在于:

This device forms a uniform liquid film through precision machined molds, and the coating thickness can be controlled at the micrometer level. According to data from a research institution, the CV value of coating thickness uniformity can be reduced to below 0.8% after adopting a variable gap die design. Its core advantages lie in:

高精度控制:激光位移傳感器實時監測模頭間隙,閉環控制系統使厚度偏差控制在±1μm以內

High precision control: The laser displacement sensor monitors the gap between the mold heads in real time, and the closed-loop control system controls the thickness deviation within ± 1 μ m

適應性強:可處理粘度范圍1-10000cPs的漿料,滿足光伏導電銀漿、鈣鈦礦前驅體等不同物料需求

Strong adaptability: capable of handling slurries with a viscosity range of 1-10000 cPs, meeting the requirements of different materials such as photovoltaic conductive silver paste and perovskite precursor

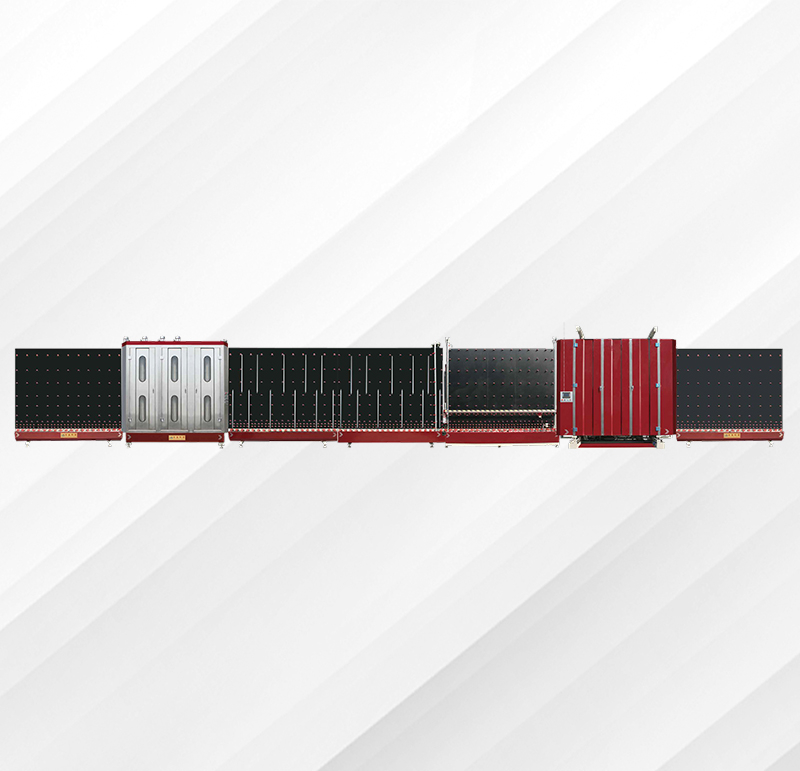

輥涂機

Roller coating machine

通過橡膠輥與鋼輥的線速度差實現漿料轉移,適用于大面積連續涂布。采用五輥轉移系統,Low-E膜層厚度偏差從±8%收窄至±3%。技術亮點包括:

The slurry transfer is achieved through the difference in linear velocity between the rubber roller and the steel roller, which is suitable for large-area continuous coating. Using a five roll transfer system, the thickness deviation of the Low-E film layer narrowed from ± 8% to ± 3%. Technical highlights include:

表面質量控制:陶瓷輥筒表面粗糙度Ra0.02μm,可避免輥痕缺陷

Surface quality control: The surface roughness of ceramic rollers is Ra0.02 μ m, which can avoid roller mark defects

節能設計:熱風循環系統使烘干能耗降低40%

Energy saving design: Hot air circulation system reduces drying energy consumption by 40%

噴涂機

Spray painting machine

利用壓電陶瓷或氣流霧化技術實現非接觸式涂布,特別適合異形玻璃加工。超聲波噴涂技術使ITO膜層方阻均勻性提升。其技術優勢體現在:

The use of piezoelectric ceramics or air flow atomization technology for non-contact coating is particularly suitable for processing irregular glass. Ultrasonic spraying technology improves the uniformity of ITO film resistance. Its technological advantages are reflected in:

柔性化生產:可編程噴頭軌跡,適應2D/3D玻璃曲面

Flexible production: programmable nozzle trajectory, suitable for 2D/3D glass curved surfaces

材料利用率高:閉環回收系統使漿料浪費率低于5%

High material utilization rate: closed-loop recycling system reduces slurry waste rate to less than 5%

絲網印刷機

Screen printing machine

通過刮刀擠壓漿料透過網版,實現圖案化涂布,采用電致伸縮刮刀后,柵線高度偏差從±3μm優化至±1μm。關鍵技術包括:

By squeezing the slurry through the screen with a scraper, patterned coating is achieved. After using an electrostrictive scraper, the height deviation of the grid line is optimized from ± 3 μ m to ± 1 μ m. Key technologies include:

網版張力控制:氣動張網系統使張力波動控制在±0.5N/cm以內

Screen tension control: The pneumatic tension system controls the tension fluctuation within ± 0.5N/cm

對位精度:CCD視覺系統實現±5μm的套印精度

Alignment accuracy: CCD vision system achieves a printing accuracy of ± 5 μ m

二、核心技術突破方向

2、 Core technology breakthrough direction

流體力學仿真優化

Fluid dynamics simulation optimization

通過CFD模擬分析漿料在模頭流道內的流動狀態,仿真優化使模頭壓力分布均勻性提升,消除涂布條紋缺陷。

By using CFD simulation to analyze the flow state of the slurry in the die channel, the simulation optimization improves the uniformity of the die pressure distribution and eliminates coating stripe defects.

在線檢測與閉環控制

Online detection and closed-loop control

集成光譜共焦傳感器與機器視覺系統,實現涂布厚度、膜層均勻性的實時監測。

Integrating spectral confocal sensors and machine vision systems to achieve real-time monitoring of coating thickness and film uniformity.

環保型干燥技術

Environmentally friendly drying technology

紅外-熱風復合干燥系統通過精準控溫,使溶劑殘留量低于50ppm,滿足RoHS標準。某藥玻生產企業的應用數據顯示,該技術使VOCs排放降低。

The infrared hot air composite drying system achieves precise temperature control to keep the residual solvent content below 50ppm, meeting RoHS standards. The application data of a certain pharmaceutical glass production enterprise shows that this technology reduces VOCs emissions.

本文由玻璃涂布機設備友情奉獻.更多有關的知識請點擊:http://www.szmdk.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.szmdk.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 玻璃涂布機設備解析:技術分類洞察 2025/06/09

- 全自動鋁條折彎機長期使用中典型出現的問題是什么,怎么解決? 2025/06/07

- 中空玻璃加工設備:立式與臥式清洗機的差異化解析 2025/06/06

- 雙組份打膠機切換膠水清潔全流程解析 2025/06/05

- 全自動封膠線輔助傳送前限位是什么意思? 2025/06/04

- 雙組份打膠機是為解決什么問題產生的呢? 2025/06/03

- 全自動丁基膠涂布機操作注意事項:細節決定品質與效率 2025/05/27

- 雙組份打膠機:解碼膠水混合后的固化時間控制藝術 2025/05/26

- 臥式丁基膠涂布機傳動系統維護要點解析 2025/05/20

- 中空玻璃加工必備8大設備詳解 2025/05/19

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us